How to glue wood like a pro.

Carpentry pros and amateur woodworkers tackling projects at home share many of the same skills. Attention to detail, patience, and steady hands are all required for success in the meticulous art of woodworking. These skills are especially important when working with glue. Glue is literally what holds it all together, and it’s as important to the end result as precise measurements and cuts. When woodworkers plan their projects and think about how to glue wood for their creations, they likely include a variety of clamps that will act as another set of hands to hold the wood in place as the glue dries. Because woodworking projects are so specialized, they often require a specific gluing method to get the job done, which in turn requires the right clamp to achieve the desired result.

A couple of factors that influence the types of clamps required for a given job are the size of the project and the clamping pressure needed while the glue is setting. When it comes to high-quality, durable, reliable clamps for woodworking projects, pros and DIYers have been relying on Pony Jorgensen clamps for more than 100 years. The following gluing methods, when paired with the right clamp for the job, will have you gluing like a pro for your next woodworking project.

Edge-gluing.

Edge-gluing in woodworking is the practice of gluing multiple boards together to create a wider panel. This is very common in woodworking, but it’s sometimes difficult to perfect without the right clamps. Implementing our suggested techniques will help ensure your edge-gluing is done properly.

First, make sure the boards are flat and square to ensure a seamless look. Arrange the boards with the best-looking side and grain pattern facing up to help hide seams. Also make sure that the end grain arches alternate up and down to help avoid warping. Before you apply glue to the boards, dry test the fit to make sure your seams match up well. Be sure to apply an even bead of glue.

Keep these tips in mind and you’ll be edge-gluing like a champ before long. In any edge-gluing scenario, the chosen clamps need to match the size of the job as well as the gluing method selected. Pony Jorgensen has a wide variety of woodworking clamps available for your next project.

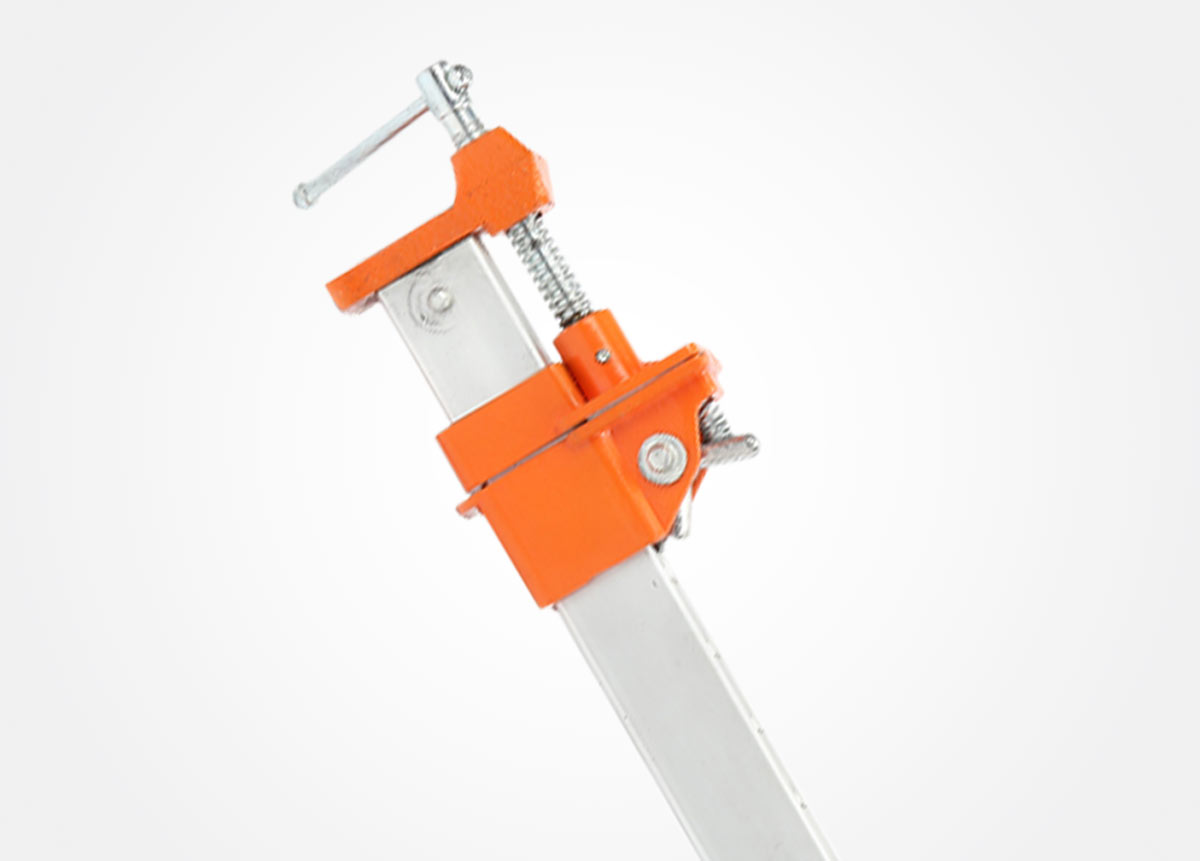

Sometimes projects call for larger clamps. When woodworkers and carpenters are edge‑gluing multiple boards, they typically turn to bar clamps. Known for their excellent strength‑to‑weight ratio, Jorgensen aluminum bar clamps are extremely strong yet lightweight, which makes them a perfect edge‑gluing solution for both commercial and DIY applications. And these clamps allow for precise adjustments to give you the perfect clamping pressure for your woodworking job. Crafted from an anodized, rust‑resistant aluminum, their design creates a stable clamping surface perfect for edge‑gluing.

When edge‑gluing jobs demand just a little bit more flexibility, many woodworkers call on Jorgensen E‑Z HOLD expandable bar clamps. These clamps are perfect for smaller edge‑gluing projects when regular‑sized bar clamps just won’t cut it. The most obvious benefit of these clamps is their rapid and easy clamping capability. But these clamps are also used for their ability to convert to spreader clamps, and they’re expandable for larger jobs. The contoured comfort grip and quick‑release lever ensure you get a firm grasp. The deep‑reach pads add that extra layer of protection to keep your work safe from any marks or dents.

Dowel joinery.

A popular method of gluing to ensure strong, accurate joints is dowel joinery. Gluing dowel joinery creates a stronger joint than using glue alone because the dowels are inserted into both pieces of wood being joined together. Bonus: the dowels are unseen, which gives you a beautiful, tight joint.

One tip for dowel joinery that should not be overlooked is dealing with excess glue. No matter how hard we try, there’ll always be some extra glue that doesn’t stay within the joint. It’s important to wipe off excess glue before it dries. Another tip is never skimping on clamps! When the job calls for two or three clamps, don’t settle for just one. You will notice a difference in how the glue sets when you use the appropriate number of clamps to hold everything in place while the glue dries.

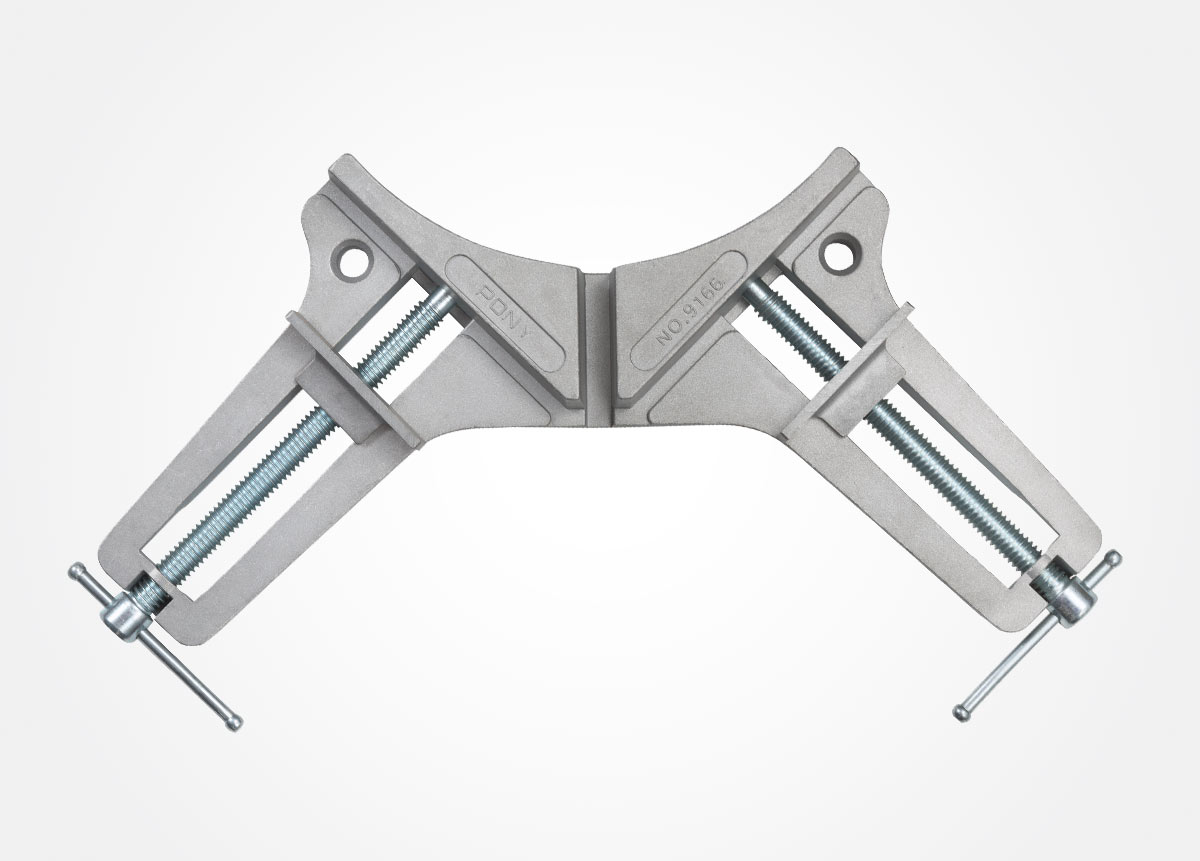

When it comes to finding the right clamp for your dowel joinery gluing project, discerning woodworkers choose Pony corner and splicing clamps. Perfect for clamping miter joints and butt joints, these clamps are made with a die‑cast aluminum frame and sliding jaws. This design allows workpieces to be held up to three inches wide, leaving joints fully exposed for dowel joinery, gluing, or nailing.

Another unique clamp option for your dowel joinery project is the Pony angle clamp with table clamps. This versatile Pony clamp is perfect for framing and cabinet assembly. Knowing the quality of your project is most important, we’ve built these clamps with plastic‑coated die‑cast jaws that won’t damage your workpiece surfaces. And because every woodworking project is a little different, this clamp’s rear jaw swivels to allow for easy adjustments based on the thickness of your material. Like all Pony clamps, the Pony angle clamp with table clamps is known for its durability and quality craftsmanship.

Check out Pony Jorgensen clamps for your next gluing project, and experience for yourself all the benefits of using the right clamps for the job. Founded more than 100 years ago and still going strong, Pony Jorgensen is the industry leader in providing durable, reliable clamps to woodworking professionals and home carpenters alike.